Daniel Davidson, MD, MBA, DBA, PHD

Introduction:

One of the most important parts of contemporary transportation are tires, which allow cars to go over different terrains safely and easily. Tire technology has advanced significantly over the ages due to advances in engineering principles, manufacturing processes, and materials. This article highlights significant turning points, discoveries, and inventions that have influenced the automobile industry as it examines the interesting history of tire technology from its birth to the present.

Early Beginnings:

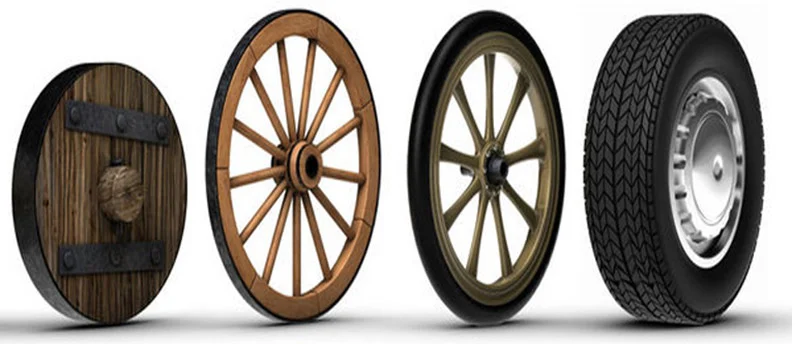

The idea of a wheel with a tire-like covering stretches back thousands of years to ancient civilizations, which is when tire technology first emerged. These primitive early tire designs were mostly constructed from materials that were easily accessible at the time, such metal, stone, or wood. These rudimentary tires were primarily designed to lessen ground friction, which would improve the efficiency of both people and cargo transportation.

- For their chariots and carts, the ancient Greeks, Egyptians, and Mesopotamians used a variety of wheel designs, frequently with metal or solid wooden discs serving as the wheel’s component. Rough terrain was uncomfortable to ride on because these early wheels lacked the cushioning and shock-absorbing qualities of current tires.

- One of humanity’s greatest technological achievements is thought to have been the creation of the wheel, which allowed for the creation of wheeled vehicles and completely changed trade and transportation. But tire technology did not start to advance into more advanced forms until much later in history.

- Pneumatic tires replaced solid tires, which was a major advancement in tire technology. Scottish inventor John Boyd Dunlop was the first to patent pneumatic tires in 1888. They consisted of an inflating rubber tube enclosed in a sturdy outer casing. Because to this invention, the ride was more comfortable and smoother because the air-filled tube dampened the impact of bumps in the road.

- Despite being a major advancement over solid tires, pneumatic tires still had drawbacks, such as being more prone to blowouts and punctures. In an effort to improve tire performance and longevity, tire makers experimented with various materials and construction techniques over time.

- With their layers of rubber-coated cloth strands laid diagonally across the tread, bias-ply tires were the norm in tire design at the beginning of the 20th century. More speed and higher temperatures made bias-ply tires more prone to overheating and uneven wear, even if they provided better traction and load carrying capacity than previous versions.

- Before radial tires became widely used in the middle of the 20th century and changed the game, bias-ply tires were still widely used despite their drawbacks. Fuel efficiency, traction, and stability were all enhanced by the steel belts on radial tires, which ran perpendicular to the direction of travel. After gaining rapid traction, this ground-breaking tire design was adopted globally as the norm for passenger cars.

Pneumatic Tires:

- Pneumatic tires are a significant development in tire technology that have transformed transportation and shaped the modern automotive sector. These tires offer many advantages in terms of comfort, performance, and safety thanks to an inflatable rubber tube enclosed in a sturdy outer shell.

- The first usable pneumatic tire was developed in 1888 by Scottish inventor John Boyd Dunlop, who established the concept of pneumatic tires in the late 1800s. Originally meant to be used on bicycles, Dunlop’s design provided a more comfortable and smooth ride than the solid rubber tires that were widely utilized at the time.

- The usage of pneumatic tires on early automobiles was adapted from their rapid popularity among bicycles. By acting as a cushion, the tire’s inflatable rubber tube reduced road surface vibrations and shocks, enhancing ride comfort and lessening driver fatigue.

- Pneumatic tires significantly improved handling and traction in addition to comfort. The rubber sidewalls’ flexibility made it possible for the tire to adjust to irregularities in the road, which improved stability and grip—particularly when braking and cornering.

- The flexibility of pneumatic tires to adjust to shifting loads and terrain is another important benefit. Drivers can maximize performance for various driving circumstances, such as highway cruising, off-road excursions, or hauling large freight, by altering the air pressure within the tire.

Because of their flexible design, pneumatic tires have natural resistance to punctures. The tire’s internal air pressure can frequently provide enough support in the case of a minor puncture to enable safe driving while repairs are completed.

Bias-Ply Tires:

Cross-ply tires, commonly referred to as bias-ply tires, are an important development in tire technology. Before radial tires became widely used, these tires were common throughout the most of the 20th century. Understanding the features of bias-ply tires is crucial to appreciating their significance in automotive history since their construction is different from those of radial tires.

Construction:

The rubber-coated fabric strands used in the construction of bias-ply tires are layered and cross at varying angles, usually between 30 and 40 degrees from the direction of travel. A strong and long-lasting structure is produced by the diagonal arrangement of the cords over the tread, sidewalls, and bead area of the tire. Rubber compounds are then applied to the layers to protect them from abrasion, wear, and the elements.

Features:

Tires with bias ply have unique features that set them apart from tires with rotation. Bias-ply tires are constructed with a stiffer sidewall, which makes sidewall flex during cornering and maneuvering more noticeable. The handling of the tire may be impacted by this sidewall stiffness, especially at faster speeds, and it may feel less responsive than radial tires.

Applications:

From the middle of the 20th century, bias-ply tires were extensively utilized in a wide range of automotive applications, such as trucks, passenger automobiles, and agricultural vehicles. In off-road, industrial, and commercial settings where puncture resistance and longevity are critical, their sturdy design and load-bearing capacity make them an excellent fit.

Radial Tires:

In the history of tire technology, radial tires mark a critical turning point. Radial tires changed the automotive industry with their unique designs and exceptional performance features when they were first introduced in the 1940s by the French tire maker Michelin. With radial tires, steel belts that ran perpendicular to the direction of travel were used instead of the fabric cords seen in classic bias-ply tires, which were organized diagonally across the tread.

Radial tires’ distinct design provided a number of significant benefits over bias-ply tires, including:

Improved Stability:

The steel belts in radial tires gave them more rigidity and stability, which made it possible to handle and manage the vehicle better, particularly when doing fast turns.

Increased Traction:

The radial design increased the tire’s contact area with the road, improving traction and grip in both wet and dry situations.

Decreased Rolling Resistance:

When radial tires were used instead of bias-ply tires, the rolling resistance was lower, which resulted in increased fuel economy and lower carbon emissions.

Extended Tread Life:

Over time, fewer tire replacements and lower maintenance expenses were incurred due to the extended tread life and less wear caused by the sturdy structure of radial tires.

Improved Comfort:

Because radial tires can absorb road irregularities and suppress vibrations, they provide a smoother and more comfortable ride.

Improved Load-Carrying ability:

Radial tires’ improved load-carrying ability is a result of their structural strength, which makes them appropriate for a variety of vehicles, including trucks, autos, and commercial vehicles.

Improved Heat Dissipation:

Radial tires’ steel belts assisted in better heat dissipation, which decreased the chance of overheating and tire failure, especially while driving over extended periods of time or when carrying large loads.

Tubeless Tires:

With many advantages over conventional tube-type tires, tubeless tires mark a substantial leap in tire technology. In contrast to traditional tires, which need an inner tube to maintain air pressure, tubeless tires form an airtight barrier that keeps air pressure inside the tire and the wheel rim separately. The majority of contemporary cars now come standard with this ground-breaking design, which has completely changed the automotive industry. These are some of the main benefits and attributes of tubeless tires:

Better Safety:

Compared to tube-type tires, tubeless tires are less likely to experience abrupt blowouts and rapid air loss. Road safety and comfort are increased for drivers when there is no inner tube present since it lowers the possibility of punctures and blowouts brought on by tube-related problems.

Weight Loss:

Since tubeless tires do not require an inner tube, they are usually lighter than tube-type tires. Because less energy is required from the engine to move the car forward, this weight reduction improves both fuel efficiency and vehicle performance.

Better Imperviousness to Punctures:

Tires without an inner tube are less vulnerable to punctures from sharp objects on the road. Furthermore, stronger sidewalls and cutting-edge tread compounds that are intended to withstand punctures and offer increased durability are common features of tubeless tires.

Superior Heat Dissipation:

The direct contact between tubeless tires and the wheel rim allows them to dissipate heat more effectively than tube-type tires. Tire overheating is less likely because to this enhanced heat dissipation, especially while driving quickly or under heavy loads.

Run-Flat Tires:

A ground-breaking development in tire technology, run-flat tires are intended to mitigate the hazards to safety and annoyance of running on flat tires. Run-flat tires are designed to withstand the weight of the vehicle even when they are fully deflated, in contrast to conventional tires, which lose air pressure when they puncture. This lessens the requirement for emergency tire replacement or roadside help by enabling drivers to travel a short distance at slower speeds in order to arrive at a safe area or service facility.

Reinforced sidewalls, which offer structural support and keep the tire from collapsing when compressed, are one of the main characteristics of run-flat tires. In order to preserve the integrity of the tire when the air pressure is lowered, these reinforced sidewalls are usually made of sophisticated materials like stiff inserts or reinforced rubber compounds.

Two primary categories of run-flat tire systems exist:

Self-Supporting Run-Flat Tires:

These tires have sidewalls that are reinforced specifically to support the weight of the vehicle even when the tire is completely deflated. After a puncture or loss of air pressure, self-supporting run-flat tires enable drivers to continue traveling for a predetermined amount of time (usually 50 to 100 miles) at a slower pace (generally up to 50 mph).

For drivers, run-flat tires have a number of advantages, such as:

Enhanced Safety:

The possibility of accidents and roadside crises brought on by unexpected tire blowouts or flat tires is decreased when using run-flat tires. After a puncture, being able to drive to a safe place helps drivers keep control of their cars and stay out of potentially hazardous circumstances.

Convenience:

With run-flat tires, motorists can avoid needing roadside assistance or an emergency tire repair and continue driving to their destination or a nearby service facility. This saves effort and time, particularly in scenarios when assistance might not be easily accessible.

Feeling of Peace:

Having run-flat tires gives drivers a sense of security and comfort, especially when they are traveling long distances or in isolated locations where tire services may be scarce.

Diminished Danger of Damage:

Using run-flat tires reduces the possibility of flat tire damage to the car’s wheels, suspension, and other parts. As time goes on, this can assist save maintenance costs and increase tire longevity.

Greater Control and Handling:

Compared to conventional tires, run-flat tires provide drivers superior control and handling because they keep their stability and shape even when they are deflated. In emergency scenarios especially, this can assist lower the chance of accidents and loss of control.

Peace of Mind:

The added security of an additional layer of protection against unplanned tire failures comes with run-flat tires, which gives drivers peace of mind.

Run-flat tires present a useful option for motorists wishing to increase their comfort and safety while driving. For many drivers, the additional benefits and peace of mind they offer outweigh the modest price difference when compared to standard tires.

Future Trends and Innovations:

Future developments in tire technology are anticipated in fields like materials science, production techniques, and intelligent tire technologies. Airless tires, integrated sensors for real-time tire monitoring, and self-healing tire compounds are just a few of the innovations that are predicted to completely change the automotive industry and redefine what is possible for contemporary cars.

Conclusion:

Human inventiveness, tenacity, and ingenuity are demonstrated by the development of tire technology. Modern radial tires and more have sprung from the modest beginnings of wooden wheels, as tire technology has consistently advanced to satisfy the ever-evolving demands of the automobile industry. In order to provide safer, more effective, and environmentally friendly transportation for future generations, tire engineers and manufacturers will keep pushing the envelope of what is conceivable.