Daniel Davidson, MD, MBA, DBA & PhD

Introduction:

The traction, stability, and safety that tires offer on the road make them a vital part of automobiles. The design and functional qualities of two popular tire types—radial and bias-ply—differ greatly from one another. Making informed judgments on tire selection and maintenance requires an understanding of the distinctions between these two types of tires. The main differences, features, benefits, and drawbacks of bias-ply and radial tires are discussed in this article.

Construction:

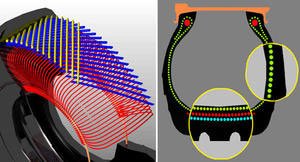

Steel belts with rubber coating that are layered and oriented perpendicular to the direction of movement make up radial tires. Better handling, cornering, and heat dissipation are made possible by these belts, which give the tire strength and stability. Bias-ply tires, on the other hand, have several layers of cloth cords positioned at angles that are opposite to the direction of travel, usually between 30 and 45 degrees. The tire structure and sidewall become more robust as a result of this construction technique.

Radial tire construction is very different from bias-ply tire construction, particularly in how the tire’s internal parts are arranged.

Tires of radial construction:

Radial tires are made up of steel belts with rubber coating that are arranged perpendicular to the direction of travel. High-strength steel wires are usually used to make these belts, and the rubber covering them gives the tire structural integrity and reinforcement. A solid, stable base is created by the steel belts, which are positioned radially from the tire’s center to the sides. Because of the tire’s increased ability to flex independently, its radial pattern offers greater longevity, handling, and traction.

Bias-Ply Tires:

On the other hand, bias-ply tires include several layers of fabric cords positioned at angles that are opposite to the direction of travel, usually between 30 and 45 degrees. Typically composed of rayon, polyester, or nylon, these fabric strands are embedded in rubber compounds. A dense, stiff structure is created by bonding and overlapping the layers of cloth cords. Bias-ply tires, in contrast to radial tires, are supported and strengthened by crisscrossing fabric cords rather than steel belts. An overall more rigid tire and a stiffer sidewall are the results of this construction technique. When opposed to bias-ply tires, the construction of radial tires with steel belts offers more strength, flexibility, and longevity. Radial tires are the recommended option for the majority of contemporary cars and driving situations since they provide greater performance attributes like increased traction, better handling, and longer tread life. Nonetheless, bias-ply tires might still be appropriate for some uses, such heavy-duty or off-road driving, where their stronger sidewalls and ability to withstand punctures are beneficial.

Performance Characteristics:

The attributes and capacities of a tire that influence its behavior and functionality on the road are referred to as performance characteristics. These features, especially those related to traction, handling, stability, and comfort, are important in determining a car’s overall performance and safety. Among the tires’ essential performance attributes are the following:

The term “traction” describes a tire’s capacity to cling to the road surface and keep it during cornering, braking, and accelerating. Better grip and control are offered by higher traction levels, particularly in slick or rainy circumstances.

Handling:

The capacity of a tire to maintain stability while cornering and navigating is referred to as handling. Good handling tires provide accurate control and consistent performance, which boosts overall driving assurance and security.

The term “stability” describes the tire’s capacity to keep a constant and even contact patch with the road surface, even when driving in a dynamic manner. Stable tires lessen the chance of skidding, sliding, or losing control by keeping the car balanced and planted.

The ability of a tire to tolerate deterioration over time, encompassing elements like sidewall strength, tread wear, and puncture resistance, is known as durability. Long-lasting tires demand fewer replacements over time, which lowers maintenance costs and downtime.

Comfort:

The ability of a tire to absorb vibrations from the road and lower noise levels to give a peaceful and comfortable ride is referred to as comfort. Having tires that are comfortable increases the enjoyment of driving by reducing tire strain and pain, especially on lengthy trips or uneven terrain.

Fuel Efficiency:

The ability of a tire to minimize rolling resistance and increase energy efficiency leads to better fuel economy and lower carbon emissions. This is known as fuel efficiency. Less energy is needed to maintain forward motion using tires that have reduced rolling resistance, which reduces fuel consumption.

Noise Levels:

Taking into account variables like tread pattern design, tread compound, and tread depth, noise levels describe the amount of noise produced by the tire as it rolls over the road surface. Quieter tires lessen cabin vibration and road noise, which makes for a more comfortable driving environment.

Wet Weather Performance:

The capacity of a tire to keep traction and grip on damp or rainy road surfaces, reducing the chance of hydroplaning and sliding, is referred to as wet weather performance. Improved wet weather performance is possible with tires using specific compounds and innovative tread designs, which boost confidence and safety in challenging circumstances.

Advantages of Radial Tires:

Improved Stability and Traction:

The cords of the tire plies in radial tires are arranged radially from the tire’s bead to the tread. In order to maximize contact between the tire and the road, this design permits a broader footprint on the road surface.

Radial tires have a bigger contact area and provide better traction, especially when braking and accelerating. Better grip on dry, rainy, or even icy roads results from this, improving the stability and safety of the car.

Enhanced Fuel Economy:

The flexible sidewalls and well-designed tread patterns of radial tires reduce rolling resistance when compared to bias-ply tires. Improved fuel efficiency is the outcome of less energy being needed to move the car forward due to reduced rolling resistance.

Radial tires often result in lower fuel consumption for vehicles, which can save money over time and lessen pollution impact.

Extended Life of the Tread and Decreased Wear:

The weight distribution of the car is more uniform throughout the tread surface thanks to the design of radial tires. This prolongs the life of the tire tread and reduces uneven wear patterns.

In contrast to bias-ply tires, radial tires are less likely to experience uneven wear like cupping or scalloping. Thus, drivers can save money on tire maintenance because radial tires usually last longer before needing to be replaced.

More Comfortable Riding Quality:

Radial tires’ flexible sides lessen impacts and vibrations caused by uneven road surfaces by acting as shock absorbers. The passengers of the car enjoy a smoother and more comfortable ride as a result.

Especially on lengthy travels, radial tires reduce driver fatigue and improve overall driving comfort because they offer superior isolation from road noise and roughness as compared to bias-ply tires.

Improved Performance in Handling and Cornering:

During cornering movements, the steel belts integrated in radial tires provide increased stability and resistance to deformation. Even at faster speeds, this enables more accurate steering response and control.

Radial tires operate consistently and have predictable handling qualities on a range of road surfaces, whether they are wet, dry, or slick. This encourages self-assurance in the motorist and makes driving safer.

Disadvantages of Radial Tires:

Greater initial cost:

In comparison to bias-ply tires, radial tires usually have a greater initial cost. This is mostly because of its sophisticated design and materials, which include steel belts incorporated into the tire’s structure. Radial tires are more expensive because of their higher production complexity and superior materials.

Sensitive to sidewall damage:

Although radial tires have better handling and traction, they may also be more susceptible to sidewall damage from hits with objects like potholes, curbs, and road debris. Radial tires’ flexible sidewalls, which are intended to improve handling and comfort, might not offer as much resistance to outside forces as bias-ply tires’ stiffer sidewalls.

Restricted applicability for off-road or heavy-duty applications:

Radial tires perform exceptionally well in on-road driving circumstances, but they might not be as appropriate for heavy-duty or off-road operations. Radial tires’ softer sidewalls might not offer the strength and endurance needed for towing trailers, traversing rough terrain, or carrying large weights. Bias-ply tires, which have a stiffer design and can support heavier weights, would be better suitable in these situations.

Sidewall puncture susceptibility:

Radial tires’ flexible sidewalls can provide improved handling and a smoother ride, but they also increase the risk of punctures from sharp objects on the road. Air leaks and possible tire damage can result from debris like nails, glass shards, or sharp objects readily penetrating the sidewall.

Sidewall bulging or deformation:

Radial tires may bulge or distort in specific situations because of the flexible sidewalls and layers of steel belts used in their production. Excessive stress on tire sidewalls can result in deformation or bulging outward when driving at high speeds, overloading the car, or hitting potholes or curbs. This may jeopardize the structural integrity of the tire, resulting in poor handling or possibly tire failure.

Reduced performance in severe temperatures:

Radial tires can have reduced performance in extremely hot or cold temperatures, even though they work effectively in a wide range of temperatures. Radial tires’ rubber compositions may soften in extremely hot weather, which may accelerate tread wear and raise rolling resistance. On the other side, as it becomes cold, the rubber could stiffen and lose its ability to provide traction and handling.

Restricted availability in specific tire sizes or applications:

Although radial tires are now the norm for the majority of contemporary cars, there can still be restrictions on their availability for specific tire sizes or niche uses. It can be difficult to obtain radial tire options for vintage or classic cars, agricultural machinery, and some off-road vehicles since they may need bias-ply tires due to special design requirements or historical accuracy.

Advantages of Bias-Ply Tires:

Bias-ply tires are a type of tire construction characterized by multiple layers of fabric cords arranged at opposing angles to the direction of travel, typically 30 to 45 degrees. These layers, known as plies, are laid diagonally across the tire’s tread and sidewall, forming a crisscross pattern. The plies are then coated with rubber and assembled onto the tire’s carcass.

In comparison to radial tires, bias-ply tires also have stiffer sidewalls. This rigidity offers more stability and support, especially when moving large objects or over uneven ground. Bias-ply tires are therefore frequently utilized in off-road vehicles, trucks, SUVs, and agricultural equipment—applications where traction and durability are crucial.

Tires with bias ply construction are renowned for their adaptability. To fit different cars and driving circumstances, they come in a range of sizes and tread patterns. Bias-ply tires can be utilized in a variety of applications, including construction equipment, trailers, and antique cars, and they offer dependable performance in a range of conditions.

Cost-Effectiveness:

Bias-ply tires are a cost-effective alternative for car owners as they are frequently less expensive than radial tires.

Puncture Resistance:

Because of its sturdy design and thicker sidewalls, bias-ply tires may provide enhanced puncture resistance in some situations, such as off-road or agricultural use.

Stiffer Sidewalls:

Compared to radial tires, bias-ply tires usually have stiffer sidewalls, which is advantageous when hauling big loads or off-road. More stability and support are offered by the sturdier sidewalls, particularly in rough terrain.

Off-Road Performance:

Because bias-ply tires are tough and can withstand harsh terrain, they are frequently found on off-road vehicles like trucks, SUVs, and agricultural equipment. They are resilient to the demands of off-road driving and provide dependable traction in difficult circumstances.

Versatility:

Bias-ply tires are adaptable and great for a lot of different uses, such as trailers, old cars, and construction equipment. To satisfy a range of purposes, they come in a variety of sizes and tread patterns and can support differing weight capacities.

Resilience:

The capacity to endure adverse conditions is a well-known attribute of bias-ply tires. Their resilience to impact damage from debris and potholes makes them an excellent option for heavy-duty and industrial applications.

Ease of fix:

Bias-ply tires are frequently easier to fix than radial tires in the event of damage or punctures. They are easier to patch or plug because to their simpler design and thicker sidewalls, which enables prompt and economical repairs.

Stability under High Loads:

Because of their sturdy design and rigid sidewalls, bias-ply tires are excellent at supporting big loads. Their dependable stability and support make them perfect for cars pulling trailers or transporting heavy loads.

Disadvantages of Bias-Ply Tires:

Decreased grip:

In general, bias-ply tires have less grip than radial tires, especially in damp or slick circumstances. Because the cords of bias-ply tires are organized diagonally, there may be less contact with the road surface, which could reduce stability and grip.

Reduced Fuel Efficiency:

Bias-ply tires may use less fuel than radial tires because of their greater rolling resistance. Bias-ply tires’ less flexible structure and stiffer sidewalls demand more energy to sustain forward motion, which eventually results in higher fuel consumption.

Increased Tread Wear:

Compared to radial tires, bias-ply tires are more likely to have abnormal tread wear patterns like cupping or scalloping. The design and manufacturing of the tire may be to blame for this uneven wear, which can shorten tire life and necessitate early tire replacement.

Harsher Ride:

Compared to radial tires, bias-ply tires usually have stiffer sidewalls and a harsher ride because of its construction with numerous layers of fabric cords. This may make driving less comfortable, particularly on bumpy or uneven roads, as the tires may cause the occupants of the car to feel more vibrations and irregularities in the road.

Limited Handling and Cornering Performance:

At greater speeds or while negotiating abrupt turns, bias-ply tires may perform less well in terms of handling and cornering than radial tires. Bias-ply tires’ structure and design may result in less accurate steering response and higher sidewall flex, which can impair overall vehicle control and agility.

Heat Buildup Susceptibility:

Bias-ply tires are more likely to experience heat buildup, particularly while traveling at high speeds for extended periods of time or when towing a large object. Bias-ply tires with overlapping fabric cords may have problems dissipating heat, which could raise tire temperatures and eventually cause tire components to deteriorate.

Restricted Selection and Availability:

Bias-ply tire options and availability may be more constrained than radial tire options due to the extensive use of radial tires in the automotive sector. This might make it difficult for owners of cars with particular needs or preferences to locate appropriate bias-ply tire options.

Conclusion:

A variety of considerations, such as the type of vehicle, the planned use, and the budget, influence the decision between bias-ply and radial tires. Bias-ply tires might still be appropriate for some uses, such off-roading or heavy-duty driving, even though radial tires provide better longevity and performance for the majority of contemporary cars and driving scenarios. Drivers may assure the best possible safety, performance, and longevity on the road by making informed selections based on their understanding of the differences between these two types of tires.